-

導航

-

電(diàn)話

-

短信

-

搜(sou)索

-

top

取(qu)消

産品展示(shi)

分類

< 返(fǎn)回列表

當(dang)前位置:首(shǒu)頁

> 産品展(zhan)示

> 冷卻出(chū)片機

冰水(shui)機

泉(quan)州聯進機(ji)械有限公(gong)司

QUANZHOU LIANJIN MACHINE CO., LTD

冰(bing)

水

機

使

用(yong)

說

明

Cooling Machine Usage

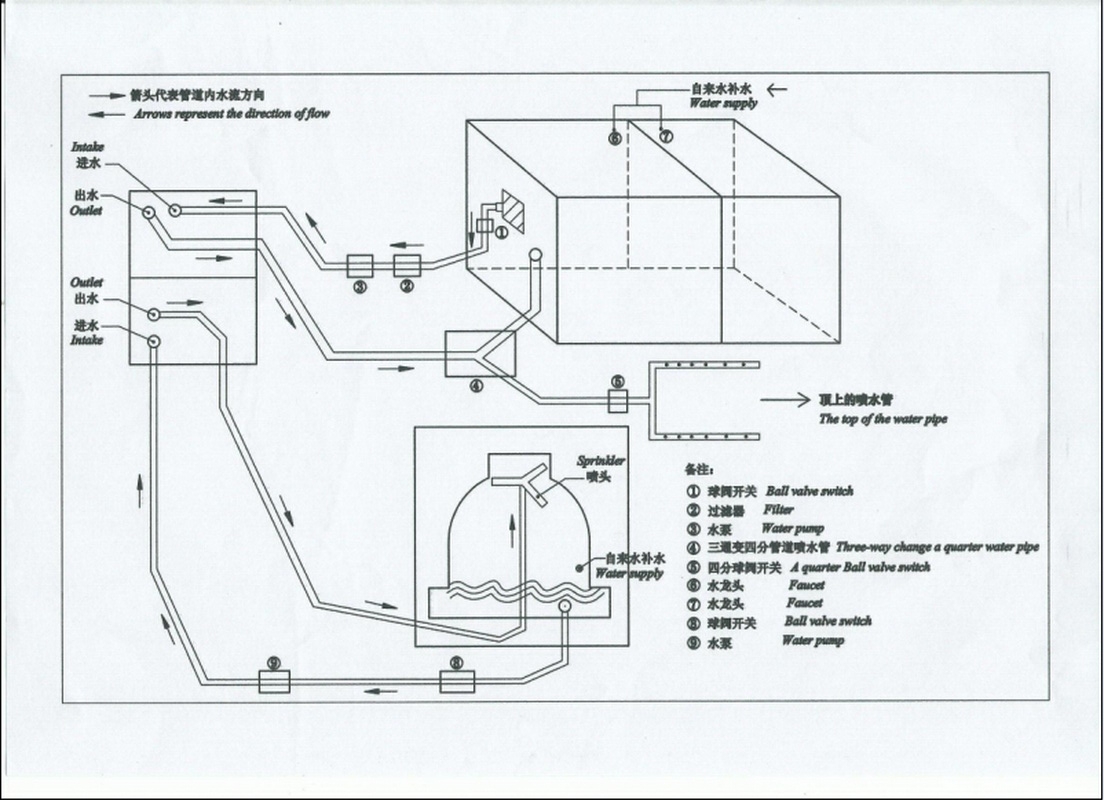

水管安裝(zhuang)示意圖 Installation schemes

用途:用(yòng)于給水槽(cao)的水進行(hang)降溫。

特點:根據(jù)水槽水質(zhì)含防粘劑(jì)化工産品(pǐn)腐蝕性高(gāo)的弊病,采(cai)用純钛管(guan)蒸發器,熱(rè)傳遞好耐(nai)腐蝕,改進(jìn)了傳統的(de)銅管蒸發(fa)器缺點。

公(gōng)共設備電(dian)力:電壓380V,50Hz。

①管(guǎn)道泵:2.2kw 兩台(tai)

②冷卻塔:15噸(dūn)

③塑料管1.5寸(cùn)到噴水管(guǎn)爲4分管

④主(zhǔ)電源線:10平(ping)方 四芯線(xian)

⑤水泵電源(yuán)線:2.5平方 三(san)芯線

主要技術(shù)參數 Technical Parameters | |

型号(hào) Model | LJ-15HP |

機型Systems | 15HP |

外型尺寸(cùn) Appearance Size: L*W*H(mm) | 1400*850*1450 |

功率Power (KW) | 11 |

重量(liang)Weight(kg) | 400 |

●上班:開機(ji)順序:提前(qian)十分鍾開(kāi)機

1. 閉合冰(bīng)水循環泵(beng)

2. 閉合熱水(shui)循環泵

3. 再(zai)閉壓縮機(jī)循環泵

●下班:随(suí)時斷電順(shun)序:

1. 斷開壓(ya)縮機

2. 斷開熱水(shuǐ)循環泵

3. 斷開冰(bīng)水泵

●移交(jiao)時:1. 高低壓(ya)的正常值(zhi)是幾公斤(jin),高低壓控(kòng)制器的設(she)定值是幾(jǐ)公斤,進行(háng)電流是幾(ji)安,設定保(bao)護值是幾(ji)安,均要記(ji)錄。

2. 機台維(wéi)修前請參(can)考以上的(de)正常值,維(wéi)修前要清(qīng)洗幹淨外(wai)觀和油漬(zi)的位置,便(biàn)于電工機(ji)修工維修(xiu)人員的操(cāo)作。

3. 空氣開(kāi)關不可以(yi)随意換大(da)的,以免燒(shao)毀壓縮機(ji)。

維修保養(yang) Maintenance

保養定爲(wei)三個月清(qīng)洗冷卻塔(tǎ)一次,十天(tiān)至十五天(tiān)更換水槽(cao)内的水,(以(yǐ)免影響材(cái)質)三個月(yue)軸承注油(you),免幹燥損(sǔn)壞,移位。

常(chang)見小問題(tí) Common small problem

●冰水循環(huán):進料的噴(pēn)水管出水(shuǐ)量小

原因(yīn):1.水槽(cao)吸水口粗(cū)過濾網賭(dǔ)了碎膠料(liào)。

2.管道過濾(lǜ)器的不鏽(xiù)鋼濾網堵(du)塞

清(qing)洗方法:務(wu)必停機水(shuǐ)泵,取出濾(lü)網清洗幹(gàn)淨。裝好方(fang)可開機。

●熱(re)水循環:手(shǒu)摸冷卻塔(tǎ)的水溫感(gan)覺比常溫(wēn)高。原因:冷(lěng)卻塔高溫(wen)狀态易産(chan)生污垢,循(xún)環水量不(bu)夠,散熱管(guan)道不通暢(chàng)。

清洗方法(fǎ): 1. 先将冷卻(què)塔底盤污(wu)垢打掃幹(gàn)淨。

2. 重(zhòng)新加水添(tian)加适量除(chu)垢劑,開循(xun)環泵運行(hang)軟化6-8小時。

3. 打開冷凝(ning)端蓋,用焊(hàn)在鋼筋上(shàng)鐵刷子刷(shuā)通管道。

4. 切記:需換清(qing)水三次,方(fang)可正常使(shǐ)用避免除(chú)垢劑腐蝕(shí)水泵元件(jian)及制冷管(guǎn)道。

●高壓跳(tiao): 1. 冷卻塔污(wū)垢積太多(duo),冷卻塔噴(pēn)水轉盤堵(dǔ)塞不轉等(děng)。

2. 水泵壞。冷(lěng)卻塔風機(jī)不轉。

3. 冷凝(níng)管道污垢(gòu)機過多。

4. 葉(ye)輪堵塞,不(bu)自動補水(shui)等以上原(yuán)因引起流(liu)動不夠,水(shuǐ)壓太小而(ér)跳。

5. 冷卻塔(ta)配套不對(dui),如十匹應(yīng)配十噸冷(lěng)卻塔。

6. 制冷(leng)劑注入量(liang)過多或更(geng)換部件時(shi)沒有經嚴(yán)格真空,系(xi)統含有空(kong)氣。

●低壓跳(tiao):1. 冰水通道(dao)堵塞(參考(kao)冰水循環(huán)排除)引起(qi)蒸發钛炮(pào)結霜。

2. 制冷(lěng)劑漏到靜(jìng)止不足五(wu)公斤時。

3. 冷(leng)媒通道微(wei)堵不順口(kou),如過濾器(qi)進出有溫(wēn)差,手閥進(jìn)出有溫差(chà)。

4. 冰水泵配(pèi)置不夠功(gōng)率。

少見故(gù)障 Rare fault

壓縮機(jī)不工作:1. 冰(bīng)水泵正常(cháng)運轉否。

2. 熱(re)水器正常(cháng)運轉否。

3. 冰(bīng)水熱水泵(bèng)均正常方(fang)能啓動壓(yā)縮機。

4. 檢查(cha)空氣開關(guān),接觸器,繼(jì)電器,壓力(lì)開關,溫控(kòng)器等電路(lu)由專業電(diàn)工檢修。

冷(lěng)炮 evaporator 熱炮 condenser風(fēng)機 fan 開水閥(fa) water valve手閥 handvalve 水泵(beng) water pump

細濾 fine filter 粗濾(lǜ) coarse filter開關 switch 噴水(shui)管 spray pipe球閥開(kāi)關 ball valve switch此不可(kě)裝開關 Don’t fix switch here.

Purpose: Used to cool the water in the sink

Advantage: According to the water quality of the flume contains anti - adhesive chemical products corrosion high disease,Pure titanium tube evaporator,Good heat transfer corrosion resistance,The shortcomings of traditional copper tube evaporator are improved.

Cooling Machine:Installation instructions

Public equipment:Power: 380V,50Hz.

●①Pipe pump:2.2kw two sets.

②Cooling tower: 15tons

③Plastic pipe(1.5inches)to water pipe(0.4 inches)

④ Host power line: 10 mm²four-core

⑤ Water pump:2.5 mm² three-core

主要技(jì)術參數 Technical Parameters | |

型(xíng)号 Model | LJ-15HP |

機型Systems | 15HP |

外型尺(chǐ)寸 Appearance Size: L*W*H(mm) | 1400*850*1450 |

功率Power (KW) | 11 |

重(zhong)量Weight(kg) | 400 |

●Start work: the steps of start-up: start up in ten minutes

1. Close the ice water circulation

2. Close the hot water circulation pump

3. Close compressor circulation pump

●After work: the steps of end power at any time:

1. Sconnect compressor

2. Disconnect hot water circulation pump

3. Disconnect the ice water pump

●Hand over:1.We should record the data as follow: the normal value of high-low pressure (kilograms),The setting value of high-low pressure controller (kilograms),The running current (amperes),The setting value of protection (amperes)

2. Please refer to the above normal values before the machine maintenance, clean cover and the position of oil in order to be convenient for repairman to operate.

3. Air switch can’t be change to a bigger one, in case of burning compressor.

Maintenance

Clean cooling tower at every three monthes, change the sink’s water at every ten days to fifteen days, (so as not to affect the material) infuse the oil into bearing at every three monthes, avoid dry damage, shift.

FAQ

●Ice water circulation: The water yield of the feed-in spray pipe is small.

Reasons: 1.The fragmentary rubber compoud is pluged up because

of the water sucking mouth of sink is thicker than dust gauze.

2. The stainless steel strainer of piping filter is pluged.

The cleaning method: Be sure to stop the pump, take out mesh to clean. Boot only after pack.

●Hot water circulation: The feeling temperature by touching cooling tower is higher than normal temperature.

Reason: The cooling tower is easy to produce dirt at high temperature, circulation water is not enough, heat pipe is obstructed.

The cleaning method:

1. First clean the cooling tower chassis’s dirt.

2. Add water and appropriate cleaner, open cycle pump running softening for 6-8 hours.

3. Open the cover of condensation, brush the pipeline by iron brush on steel bar.

4. Remember: change clear water three times to avid that cleaner corrode pump components and refrigeration pipeline corrosion.

●High pressure jump:

1. The cooling tower has too much dirt, the water spray of the cooling tower is jamed and not work.

2. Water pump doesn’t work. The fan of cooling tower doesn’t work.

3. Condensation pipes have too much dirt.

4.Impeller congestion, not to be automatic to fill water etc, these reasons cause the water flow is not enough, and water pressure is too small to lead to jump.

5. Cooling tower is in supporting the wrong horse, such as ten horse should match ten tons of cooling tower.

6. The injection quantity of refrigerants is too much or when replace parts without the strict vacuum, containing the air in the system.

●Low pressure jump

1. The cool water channel is jamed (reference ice water circulation to exclude) which cause evaporation titanium gun frost.

2. Refrigerants lead to the static is not to have five kilograms.

3. Cold channels micro plug, such as filters have different temperature in into and out of.

4. Ice water pump configuration doesn’t reach enough power.

Rare glitches

Compressor doesn’t work:

1. Whether the ice water pump works normally.

2. Whether the hot water pump operates normally.

3. he compressor can only be started after the ice water pump and hot water pump surely work normally.

4. Check air switch, contactor, relay, pressure switch, the thermostat and other circuits are checked and repaired by professional electricians.

泉(quán)州聯進機(jī)械有限公(gōng)司

技術支(zhī)持:廈門易(yì)爾通網絡(luò)科技有限(xiàn)公司泉州(zhōu)分公司 信(xìn)息支持:東(dōng)南商機網(wǎng)

京ICP證000000号

泉州聯(lián)進機械有(you)限公司

技(jì)術支持:廈(shà)門易爾通(tōng)網絡科技(jì)有限公司(si)泉州分公(gōng)司 信息支(zhī)持:東南商(shang)機網

京ICP證(zhèng)000000号